Exploring Full Composite Construction

in Caravans

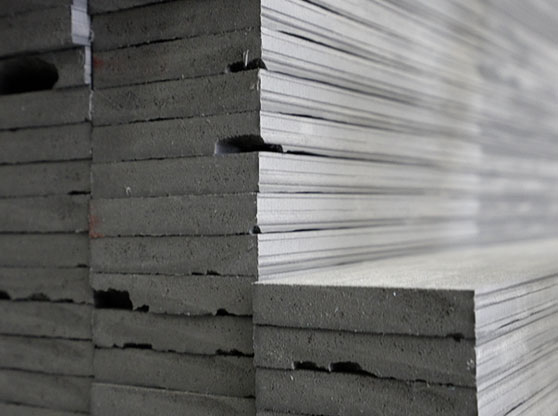

Full composite construction is a cutting-edge approach in the realm of caravan manufacturing. This technique abandons the traditional framing methods and instead utilises advanced materials to create robust and lightweight caravans. Essentially, full composite construction involves bonding multiple layers of different materials to form the structural panels that make up the caravan’s floor, walls, and roof.